The epidemic that is affecting us will certainly mark the history and we hope it will be less by its gravity than by the changes it will bring to our societies. Innovations are already flourishing to help all of us.

Like other outbreaks before it, it is very likely that the coronavirus pandemic will bring profound changes in our society.

Beyond the huge economic losses caused by this health catastrophe, some positive notes could be expected in terms of innovation, as it has been the case before. It is said that the clocks, for example, have appeared in the aftermath of the important epidemic of black plague in the 14th century, to keep track of the survivors’ working time. “Modern” medicine too, because it went away from the principles of healing through prayers only. What about the smallpox vaccine? It appeared a few decades after the smallpox epidemic in Boston in the 18th century and the controversy on the inoculation, an unreliable preventive treatment.

More recently, the SARS outbreak in 2002 fostered the development of e-commerce in China (especially for Alibaba), but also the temperature controls at airports which allowed Asia to be rather spared by the Covid-19.

Today, with coronavirus, many talks about the standardization of teleworking. But if it still used after the crisis, other questions will arise about its incidence on our lifestyle. And what about home delivery, telemedicine and online leisure activities, which are also growing rapidly?

Another consequence of the epidemic: businesses are getting involved, sometimes modifying their activity and innovating to win this medical war.

Start-ups giving assistance to hospitals

Start-ups are very active in the fight against Covid-19. Some have immediately reacted to the situation by innovating more and highlighting new products to limit the epidemic.

Estimote, for example, commercializes trackers with GPS and proximity sensors in order to monitor interactions between work colleagues and reduce the risk of contamination. Also, to help with protection, a new process for manufacturing masks with transparent visor has been developed at the FabLab of the Lab’O in Orléans (France). It is faster than before.

Still with the view of limiting the epidemic, a miniature and portable laboratory was created in the United States by Abbott laboratories. Called ID NOW, this testing robot, presented with great fanfare by Donald Trump himself, allows to determine whether the patient has coronavirus or not in five minutes’ time.

3D printing is also very useful during this period, for manufacturing or quickly adapting medical equipment. In just a few days was set up the 3D COVID project in collaboration with the hospitals in Paris and the start-up Bone3D, in order to manufacture up to 3,000 objects per week thanks to several tens of 3D printers.

Telemedicine benefits from lockdown as well. Thus, the eHealth startup Cureety recently announced a fundraising of 1.2 million euro for the remote monitoring of patients and the rules for access to teleconsultation have been softened by the French government, allowing this activity, still in its infancy, to suddenly represent 500,000 consultations per week. It is hard to imagine taking a step backwards after that.

We also note a more frequent use of robots. In Italy, a hospital uses one to deliver patient care. At the same time, some organizations are starting to use robots to clean up certain places quickly and safely. In Singapore, robots are replacing waiters in restaurants to limit the risks of spreading the virus.

Finally, other tools and applications are emerging, used for example to reduce waiting times in shops or to study the spread of virus. The SAFE Cluster published here (in French) some solutions to deal with the crisis: https://www.safecluster.com/wp-content/uploads/2020/04/CATALOGUE-SOLUTIONS-V1-3.pdf

Companies that transform their activity

Respirators, masks or hydroalcoholic gel are particularly sought at the present time.

To meet the high demand, some companies of all sizes have decided to modify their activity for some time. The LVMH Group was one of the first to produce a large quantity of alcoholic gel for free thanks to its perfumes and cosmetics production units.

The accelerated manufacturing of respirators also mobilized engineers: if in the United States General Motors was requisitioned, other groups acted spontaneously like Seat in Spain (which developed a model from wiper motors). In the UK, dozens of companies have responded to the government’s call to manufacture homologated ventilators or design new models.

Another diversion, in France and in Italy: the Decathlon snorkeling masks have been transformed into a respirator accessory thanks to small elements printed in 3D.

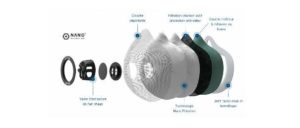

Lastly, regarding the protective masks, several French companies specialized in weaving have turned to the manufacture of cloth face masks, such as Les Tissages de Charlieu or the lingerie brand Empreinte, among others. More unexpectedly, Michelin also launched a mass production of masks, the filter of which can be removed and washed about 20 times. The objective is also to produce less waste with a cost divided by 5 compared to disposable FFP2 masks.

R-Pur, a start-up already specialized In the manufacture of anti-pollution masks which are more efficient than the FFP3 standard, is looking for additional production sites to install its machines and readjust its masks for health professionals.

We will finish this article with a societal modification: the development of e-commerce. Many restaurant owners or even farmers have decided, to maintain a minimum of activity, to offer delivery or pick-up services. For many customers, it was their first experiment of this type of shopping.